![]()

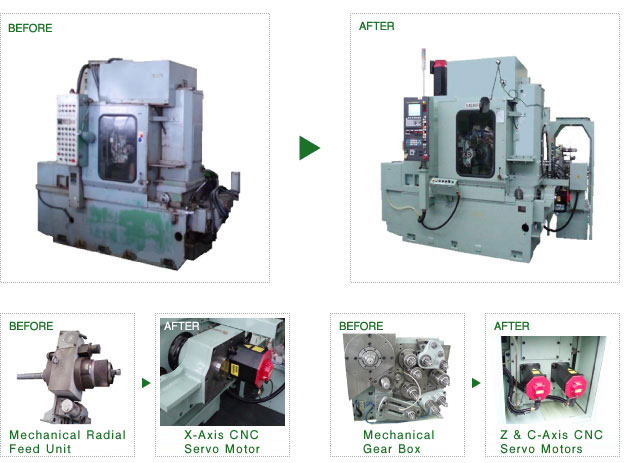

The mechanical radial feed unit and gear box are removed, and X-axis (radial), Z-axis (axial), C-axis (work table) and B-axis (Hob) are retrofitted with CNC functions, delivering significantly improved operability and productivity.

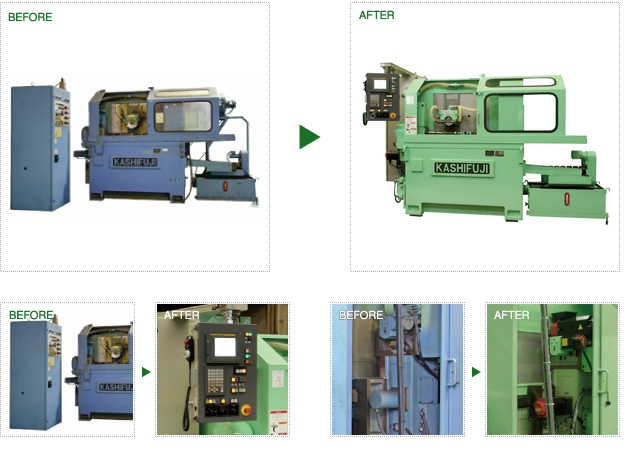

The integrated operator panel and machine body has a smaller foot print, delivering increased operability.

By replacing the pulse motor control with CNC, a wider working range is automatically controlled, and the speed of each axis is increased.

Additionally, an auto checking device confirming the number of flutes prevents a hob/program mistake which can damage the hob and/or grinding wheel, allowing increased working efficiency and safety.

Kashifuji completely disassembles your machine to clean each component, and check the degree of aging or accuracies on each unit. Each unit is modified, or replaced with a new unit depending of the results of a thorough investigation. The accuracies of important machine components are carefully double-checked.

Moreover, the information on machine design, machine rigidity and machining accuracies accumulated over many years of after-sales service/support is incorporated in the overhaul of your machine. The end results produce a rebuilt machine that is more accurate than the original!