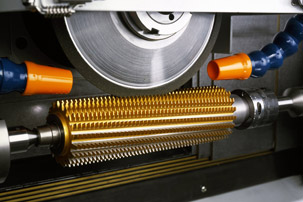

KG2530 4 or 6 Axis-Hob Sharpening Machine

A Precision Hob Sharpener

・ HSS Hobs

・ Carbide Hobs

・ Cermet Hobs

KG253L Grinding Wheel Truing by NC Dresser

KG253 Automatic Positioning of

Hob and Grinding Wheel

KG253 Hob Sharpening

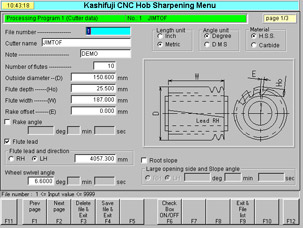

The 6 axis-KG253L can swivel the grinding wheel head from +/- 25 degrees, allowing the helical fluted hobs to be sharpened. Also, an optional Rotary Type NC Dresser allows CBN grinding wheel dressing. The shapes of the grinding wheels are automatically calculated by the , and the dressed grinding wheels deliver highly accurate sharpening of cutting faces. For straight gash hobs, the 4 axis-KG253S is available.

(Hobs with a Rake Angle)

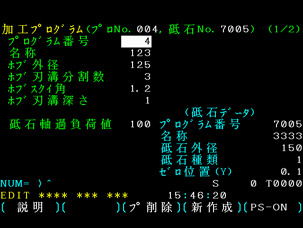

By Program input, the grinding wheel offset amount is automatically calculated and positioned depending on the hob rake angle.

(Carbide Hobs with a Negative Rake Angle)

Hobs ranging from +10 to -45 degrees of rake angle (equivalent to +20 mm~-90 mm of the offset amount) can be mounted and sharpened. Skiving hobs that require a large negative offset amount can be easily set.

Prior to the sharpening process, the grinding wheel is positioned between 2 flutes of the hob by manual. The grinding wheel face is then automatically positioned against hob face to be ground.

Program input is easily performed via conversation type programming. Also, a built-in PC type NC device and 10.4 inch color liquid crystal panel are utilized in the KG253L.