KGC2 4 Axis-Grinding Center

A Multi Purpose Grinding Machine suited for Cylindrical and Internal Grinding, Internal Gear Grinding and Internal Spline Grinding

・ Cylindrical Grinding

・ Internal Grinding

・ Internal Gear Grinding

・ Internal Spline Grinding

The KGC2 Grinding Center was developed to consolidate various machining processes for parts that need a versatile mechanical processing, which allows highly efficient/accurate multi-grinding by making maximum use of NC capability. Additionally, machine features such as, superior thermal rigidity, torsional rigidity and vibration resistance are ideally suited for parts that require complicated and versatile machining processes. Cylindrical and internal grinding are available in a single chucking on the KGC2. Internal gears and internal splines can be ground with a high degree of accuracies by utilizing an excellent indexing control technology.

Cylindrical grinding is performed by vitrified CBN grinding wheels. A broad range of high-precision spindles are available for grinding wheels ranging from 50 to 200 mm in diameter. Dressing can be done on board with the use of a diamond rotary truing device. Unlike an ATC-type grinding center, the KGC2 does not require dressing after every cycle, allowing the wheel life to be greatly increased.

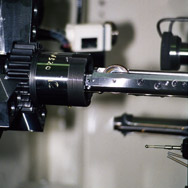

Internal grinding is also performed by vitrified CBN grinding wheels. A broad range of spindles designed for 12~60-mm-diameter wheels, as well as arbors for various hole shapes, are available. The photo shown below is a 25-mm-diamter wheel mounted on a 125-mm-long arbor, which is installed in a high-frequency spindle providing 30,000 rpm. For both cylindrical and internal grinding operations, grinding wheels with optimum shapes, abrasive grains, and bonds can be offered depending on individual part specifications.

Internal spline grinding is performed by CBN electroplated grinding wheels. The cross-sectional shapes of the wheels such as angular, involute and circular etc. are determined depending on the part specifications. A broad range of wheels are available for internal diameters ranging from 30 to 300 mm. In case of sizes, please consult us.

Internal gear grinding can be performed on internal gears with diameters ranging from 30 to 300 mm. Moreover, the KGC2 can be equipped with two types of wheel spindles for rough and finish grinding simultaneously, allowing efficient internal gear grinding with extremely accurate surface finish.

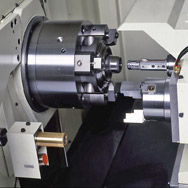

Auto part chucking operation starts accurately and safely by only inserting a part on the part station without operator's direct manual part chucking. The chucking devices can be selected from; air-chucks, hydraulic chucks, diaphragm chucking, collet chucking, grease arbor chucking and face clamp chucking etc.

Also, by utilizing various types of sensors, the machine prevents wrong part loading in the production line including two similar types of parts, or improper part positioning during loading.