KGV151 4 Axis-Shaft Groove Grinding Machine

Extremely Productive in Grinding CVT Ball Tracks High Machine Accuracy with Tremendous Grinding Speeds

・ CVT Pulley Shafts

・ Splined Shaft Parts

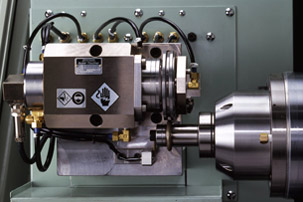

A 30,000 rpm(max) grinding spindle offers a performance advantage over grinding with the use of electroplated CBN grinding wheels or small diameter (dia. D 45~100 mm) Vitrified CBN Grinding Wheels. This allows a shaft part with a tight radius to be easily ground. Large roller bearings utilized in the main spindle allow high rigidity and accuracy. The full closed-loop system on the X-axis (radial direction) creates highly accurate positioning. Additionally, the special guideways used on the Z-axis (axial direction) eliminates waviness which can occur when linear guideways are used.

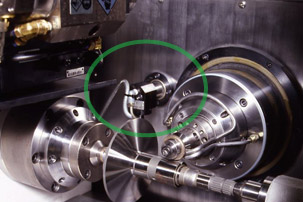

Fast and stable part orientation is automatically performed by a non-contact type sensor. A contact type sensor (a touch probe) can be also utilized depending on the shapes of the grooves, delivering more accurate part orientation.

The grinding wheel position is automatically checked and compensated to reduce variations caused by thermal growth, producing stable machining accuracies from a machine cold start (Y-axis compensation). Also, an in-processing checking/compensation is performed by directly checking the ground grooves (X and Y-axis compensation).

A Vitrified CBN grinding wheel can be dressed on board by a profiled diamond dresser. An AE (Acoustic Emission) sensor and closed loop Y and Z-axis allow highly accurate dressing.