KA220/400 6 Axis-CNC Hobbing Machine

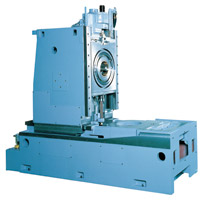

Designed for Heavy Duty Hobbing of Medium Sized Gears An Extremely Rigid Hobbing Machine

- Features

- Vertical Hob Machine

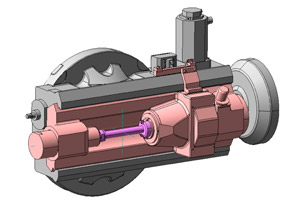

- Zero backlash Table

- Hand sclaped guidways

- Hard hobbing

- Programming

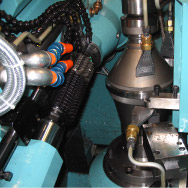

- Autmation

・ Large Automotive Transmission Gear (Ring Gear etc.)

・ Truck Gear

・ Agricultural Machine Gear

・ Construction Machine Medium Sized Gear

The rigidly designed hob head and hob saddle assure consistency in hobbing accuracies during heavy duty hobbing.

The machine bed employs double-walled structure with suitably designed ribbing. Additionally, the long and wide guideways prevent column distortion due to cutting forces generated during heavy duty hobbing.

The maximum module on the KA220/400 as standard specifications is 8, however larger pitch gears of more than 8 module can be successfully hobbed by using the multi-cut hobbing cycle. (We have ample experience in hobbing M16 Gears).

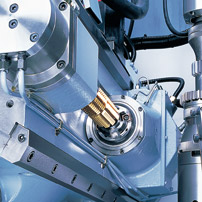

By using Dual Hobs mounted on a single arbor (HSS hob for roughing and a Cermet Hob for finishing),a highly accurate finished gear can be achieved, eliminating the shaving process. Moreover, the Cermet hob cutter effectively prevents "Built-Up" cutting edges (workpiece material welding to the hob's cutting surface) during the hobbing cycle.

Also, a Carbide Skiving hob cutter having a negative rake angle can be used to finish heat treated (hard) parts.