KL1000 6 Axis-CNC Hobbing Machine

A Versatile Hobbing Machine suited for Large Sized Gears

- Features

- Vertical Hob Machine

- Zero backlash Table

- Hand sclaped guidways

- Hard hobbing

- Programming

- Autmation

・ Construction Machine Gear

・ Marine Gear

・ Large Reduction Gear

The double-walled machine bed with suitably aligned ribbing has wide guideways supporting the work table saddle. The column resists cutting forces as it is securely fixed to the machine bed creating a dynamical structure. Also, the machine structure is designed to reduce distortions caused by thermal changes. This dynamic rigidity delivers excellent thermal stability, which minimizes the lead variations caused by heat buildup when hobbing large pitch gears with a long cycle time.

The core units of a hobbing machine (work table & work table saddle) have a rigid design allowing superb rotational accuracy during heavy duty hobbing for many years. Moreover, the diameter of the Master Worm gear is 12% larger than its predecessor improving hobbing accuracies. Outstanding manufacturing technologies and superb assembly techniques, accumulated over many years of hobber manufacturing, are incorporated into those core units, which produces excellent hobbing accuracies.

The tailstock column is easily retracted out of the way by means of a ball screw, which creates clearance for 1,000 mm diameter gears. Additionally, the tailstock arm is hinged, allowing an easy loading/unloading of a large diameter/pitch gears.

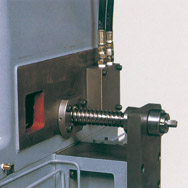

By using Dual Hobs mounted on a single arbor (HSS hob for roughing and a Cermet Hob for finishing), a highly accurate finished gear can be achieved, eliminating the shaving process. Moreover, the Cermet hob cutter effectively prevents "Built-Up" cutting edge problems (workpiece material welding to the hob's cutting surface) during the hobbing cycle.

Also, a Carbide Skiving hob cutter having a negative rake angle can be used to finish heat treated (hard) parts.